An industrial organisation’s guide to energy management

Read time: 8 minutes

Energy is a topic that is increasingly present in our lives, both personal and professional, and it is likely here to stay. Jordan Cooper, Product Manager at Pilot Group, looks at energy management, the terminology, the technology, challenges, and benefits that can be realised. With energy becoming increasingly important in business success, the savings that can be achieved through reductions in wasteful energy consumption are essential.

In this guide we will look at:

1. What is meant by energy management?

2. Where should I begin with my business’s energy management?

3. What is an energy control system?

4. How do I control high energy consuming equipment?

5. What savings can I expect from an energy control system?

6. The importance of energy efficiency and sustainable solutions.

7. What should my next steps be to better manage my energy?

Jordan Cooper from The Pilot Group offers their expertise on the energy management opportunity, demystifying the technology and highlighting opportunities including cost savings, business resilience and increased staff engagement.

Energy management is such a vast topic, and it can be challenging to find a starting point. By using the goal of saving energy as the focal point of the conversation it gives us a clearer path.

In general, energy management can mean anything from monitoring, controlling and/or analysing your energy usage. Often, it centres around the use of the information you have collected to optimise your energy performance and lower your overall consumption. This can simply mean looking at monthly or quarterly bills from your provider and making reactive changes, all the way up to implementing a system that controls this for you proactively.

Other relevant terminology:

Always start by understanding your energy usage. This could be through gathering your monthly bills or implementing an energy monitoring solution. If you don’t have a reference point, it is very difficult to gauge if any changes you make are successful. Gathering this baseline is therefore essential. The simplest way you can start to gather baseline data is with your monthly energy usage data. If you don’t have any data or technology already in place, ask your energy provider for your half-hourly energy bills. Most businesses will have meters with this capability, and it allows you to look at not only how much you are consuming but also when, such as during the day, week and month.

If you know the operations of your business, it then allows you to question the peaks and the timings of your consumption. Are you using more energy than makes sense outside of operating hours? Do some days have much larger spikes in use than others?

While understanding your energy profile and usage is a great start point, it doesn’t result in any savings. To achieve that you need to exert control and management of the equipment using the energy. Depending on the size of your business and the volume and intensity of equipment, this may require careful consideration in order to deliver the appropriate optimisation’. However, for most industrial scale businesses this is where an energy control system will start to look very attractive by centralising control and optimising the behaviour.

Jordan Cooper, Product Manager at Pilot Group

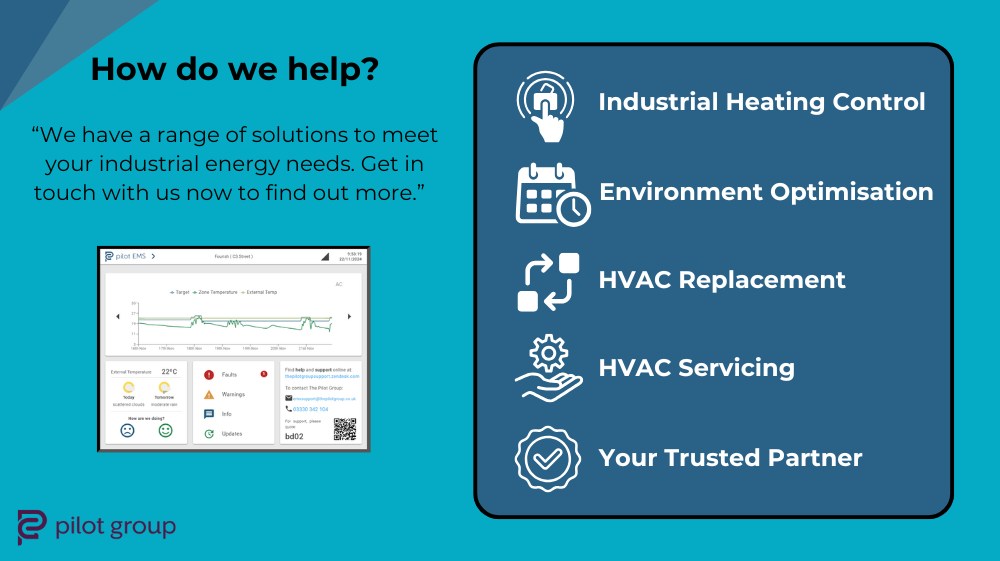

An Industrial Energy Management System is a centralised control system for all of your energy intensive equipment at site. This may include industrial heating and cooling equipment, industrial air compressors, lighting and fans (such as destratification and extract).

The Energy Management System will integrate and control these equipment types so that they are scheduled to behave as required, this can be in terms of start stop times, intensity of performance and/or optimizing the set up based on site needs throughout each day and beyond.

The system should be able to be easily updated by the responsible person at site, such as the site manager. It will result in controlled costs and optimal business performance with the minimal amount of effort to do so. It is important that only the right people can access the system, if too few people can access there is a risk of ‘lock out’ if people are on holiday or leave the business. If too many people have access it may dilute the ownership or result in configuration wars in the ffactory space, especially if individuals aren’t aligned. This is something we see very often, especially around heating that can be avoided.

One of the best places to start is by looking at those high-energy-consuming items and establishing if they are controlled manually, on a timer, or with a central point of control. It’s often the case that schedules for equipment and heating were set a long time ago and don’t reflect the current operational hours of the business and in some cases where they are controlled manually, they are left switched on and operate constantly.

This is where pieces of technology like an Energy Management System or Building Management System (BMS) can really help. These systems vary with some pulling all of the consumption data into one place and others that allow for better control of your equipment.

One area I have seen a lot of success during my time at Pilot Group is looking at heating. Industrial heaters such as warm air blowers and radiant tubes are often used inefficiently, and the implementation of a Pilot Group Energy Management System has seen gas bills for heating reduced by an average of 43%. An energy control system like Pilot Group’s not only gives you a central point of control for all of your heaters, but your entire HVAC estate (this includes items such as air compressors, destratification fans, air conditioning units, lighting and more), it also uses smart technology to actively lower your energy consumption.

Expert tip: Check your heater efficiency rating, which is usually found on the service sticker. You could have the best control strategy in the world but if your heater is inefficient, you may be wasting a large amount of energy.

Every energy control solution will be slightly different, with features shaped towards slightly different challenges for the customer. A few examples of how an intelligently controlled system such as an EMS can generate savings are:

Other benefits that could be expected from an intelligently controlled system include:

In summary, solutions which optimise environment and energy consumption are only going to grow with importance as the world becomes more sustainability focused. Cost has always been a key driver for business, and this is unlikely to ever change. Control and optimisation of energy systems improve business performance and drive success.

There is no one single ideal starting point, but if you are unsure of your energy profile and consumption - this is a sensible place to begin. If you are ready to start driving savings now, explore a control system for your high energy usage items. Getting the optimal set up may take time and once achieved will become a constantly evolving process based on your operational requirements.

It is always important to note that sustainable solutions only work as well as they are configured, updated and interacted with. If your business and any relevant teams don’t engage with the controls put in place, or actively work against them, the solutions will not work well in practice (Imagine installing a new heater, then leaving the window open all day).

Energy control solutions are a great step towards optimizing your energy consumption for equipment such as industrial heating, however, they are also a step towards net zero. Other solutions such as renewables generation, insultation improvements, site processing optimisation, onsite transport optimisation will drive this forward, and by addressing your full business operations frameworks and understanding your Scope 1,2and 3 emissions you will have a better understanding of the complete decarbonisation picture.

The Pilot Group are a Manchester based business with over 20 years’ experience, focused on sustainable solutions. For more information about the Pilot Group visit their website.